Read the full article to gain deeper insights and comprehensive information.

Jan 29, 2026

0

Learn how to start a kulhar making business with just ₹50K investment and earn ₹2 lakhs monthly. Complete guide covering machinery, raw materials, licenses, marketing & sales strategies. Get MSME loan info, railway supply contracts & business setup tips for Bihar & India. Step-by-step kulhar pottery business guide 2026.

Introduction

The kulhar and clay utensils business in India is not only traditional but also a rapidly growing opportunity in today's eco-friendly era. As a biodegradable alternative to plastic, the demand for kulhars is continuously increasing at railway stations, tea stalls, events, and hotels. This guide will provide you with all the essential information to start this business.

Market Demand:

Business Advantages:

1. Cottage/Micro Industry Level

2. Semi-Automatic Unit

3. Commercial/Factory Level

Main Materials:

Raw Material Costs:

Step 1: Clay Preparation

Step 2: Mixing

Step 3: Molding

Step 4: Drying

Step 5: Firing

Step 6: Finishing

Step 7: Packaging

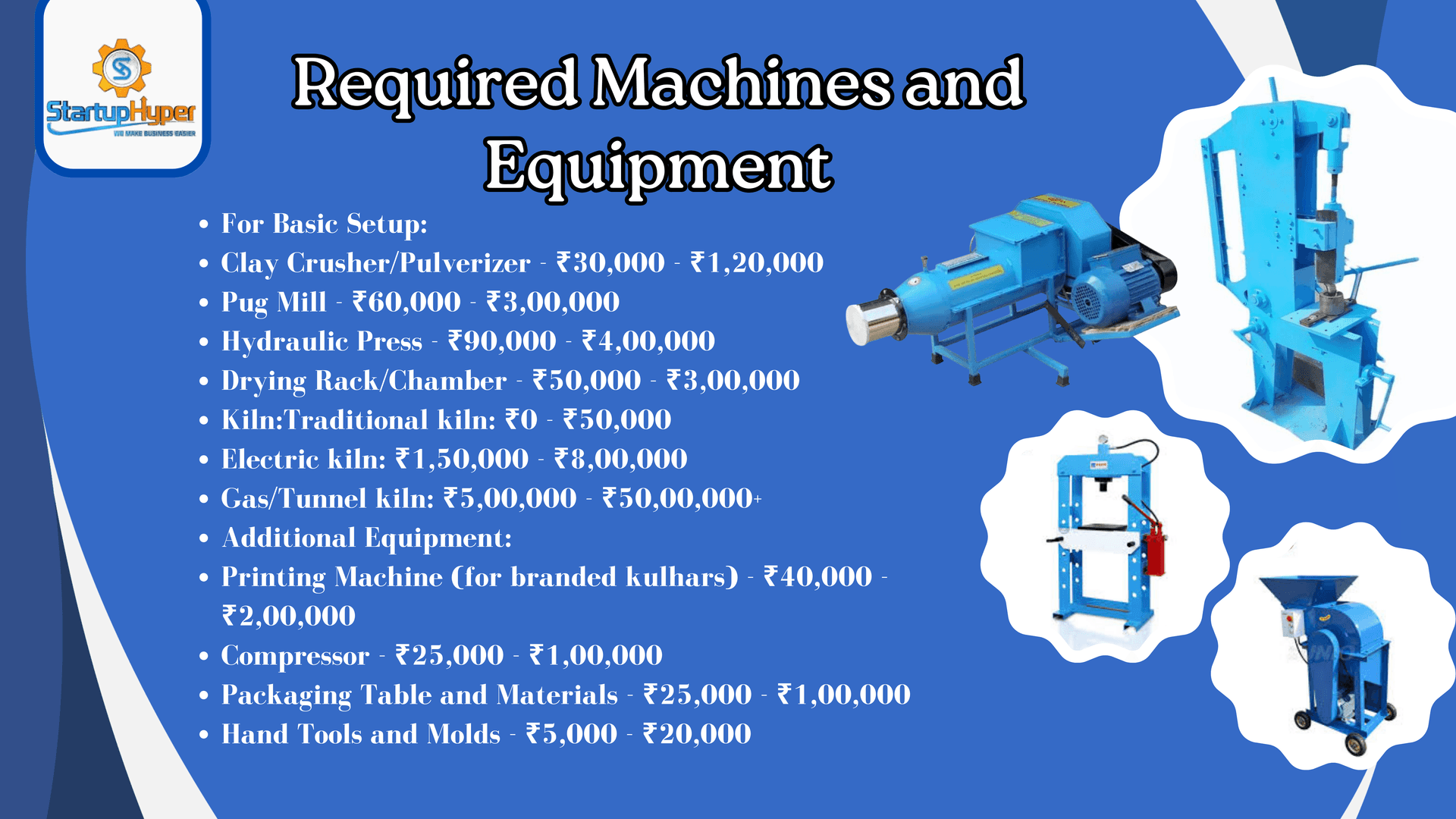

For Basic Setup:

Kiln:

Additional Equipment:

Detailed Investment Breakdown

Small Scale (Cottage Level):

Medium Scale (Semi-Automatic):

Large Scale (Commercial Factory):

Profit and ROI Calculation

Monthly Expenses:

Monthly Net Profit: ₹14,000 - ₹25,000 Annual Profit: ₹1,68,000 - ₹3,00,000 ROI (Return on Investment): 6-12 months

Note: Branded or printed kulhars can be sold at ₹6-₹15, doubling the profit margin.

Marketing and Sales Strategy

Local Market:

Bulk Buyers:

Online Sales:

Branding Methods:

Challenge 1: Cracks During Drying

Solution: Use controlled drying chamber, slow drying process Challenge 2: Rising Fuel Costs

Solution: Invest in electric or gas kiln, use solar energy Challenge 3: Seasonal Demand

Solution: Build stock for festivals, diversify product range

Challenge 4: Competition and Price Pressure

Solution: Branding, quality, customization services

Challenge 5: Shortage of Skilled Workers

Solution: Train local potters, contact ITI institutes

PMEGP (Prime Minister's Employment Generation Programme)

Mudra Loan

MSME Subsidy

Stand-Up India

Week 1:

Week 2:

Week 3:

Week 4:

Success Mantras

The kulhar and clay utensils business is a profitable and eco-friendly venture. Starting with a small investment, it can be gradually scaled to a large level. With proper planning, focus on quality, and good marketing, this business can provide you with stable income and growth opportunities. With increasing awareness about environmental protection, the future of kulhars and clay products is bright. If you take this business seriously and keep improving continuously, success is assured. Best Wishes!

Bihar's Most Trusted & Best Machinery Supplier Company

Ready to start your kulhar business? StartupHyper provides complete machinery solutions for entrepreneurs in Patna and across Bihar. We supply quality kulhar making machines, clay processing equipment, and offer end-to-end business setup support.

Premium Machinery Range:

✅ Kulhar Making Machines (Manual & Automatic)

✅ Clay Pug Mill & Processing Equipment

✅ Hydraulic Press with Molds

✅ Electric Kilns & Gas Furnaces

✅ Drying Chambers

✅ Printing & Branding Machines

✅ Complete Production Line

Complete Business Support:

✅ Free Installation & Setup Guidance

✅ Worker Training Programs

✅ Raw Material Supplier Network

✅ Market Linkage (Railway, Hotels, Events)

✅ MSME Loan & Subsidy Assistance

✅ Business Consultation & Planning

✅ After-Sales Technical Support

Why Choose StartupHyper?

🏆 500+ Successful Business Setups

🏆 ISI Certified Quality Machines

🏆 Best Price Guarantee

🏆 Delivery Across All Bihar Districts

📞 Contact Us Today:

☎️ 9472093913, 9263800297

📧 officestartuphyper@gmail.com

Start Your Kulhar Business with Bihar's #1 Machinery Supplier!

MSME Registered | Trusted by 500+ Entrepreneurs

💬 Book Your FREE Business Consultation Now!

Stay updated with the latest tips, trends, and best practices in factory setup and machinery procurement—subscribe to the StartupHyper newsletter!

No spam, we promise. Your inbox is safe with us—only valuable insights.